execution of horizontal and vertical waterproofing embedded in the ground of parts of buildings and structures (e.g.fast insulation under water pressure - 1 bar after 24 hours.the possibility of gluing protective boards after 4 hours.tank filling in: after 24 hours (at +23 C and 50% relative humidity) application (air and substrate) temperature from +3 C to +30 C.processing time ~ 45 min (at +23 C and 50% relative humidity).density of ready-mixed mortar ~ 1.05 kg / dm 3.resistance to road traffic and low temperatures.setting and hardening due to chemical reaction.the number of applied layers is a minimum of 2.

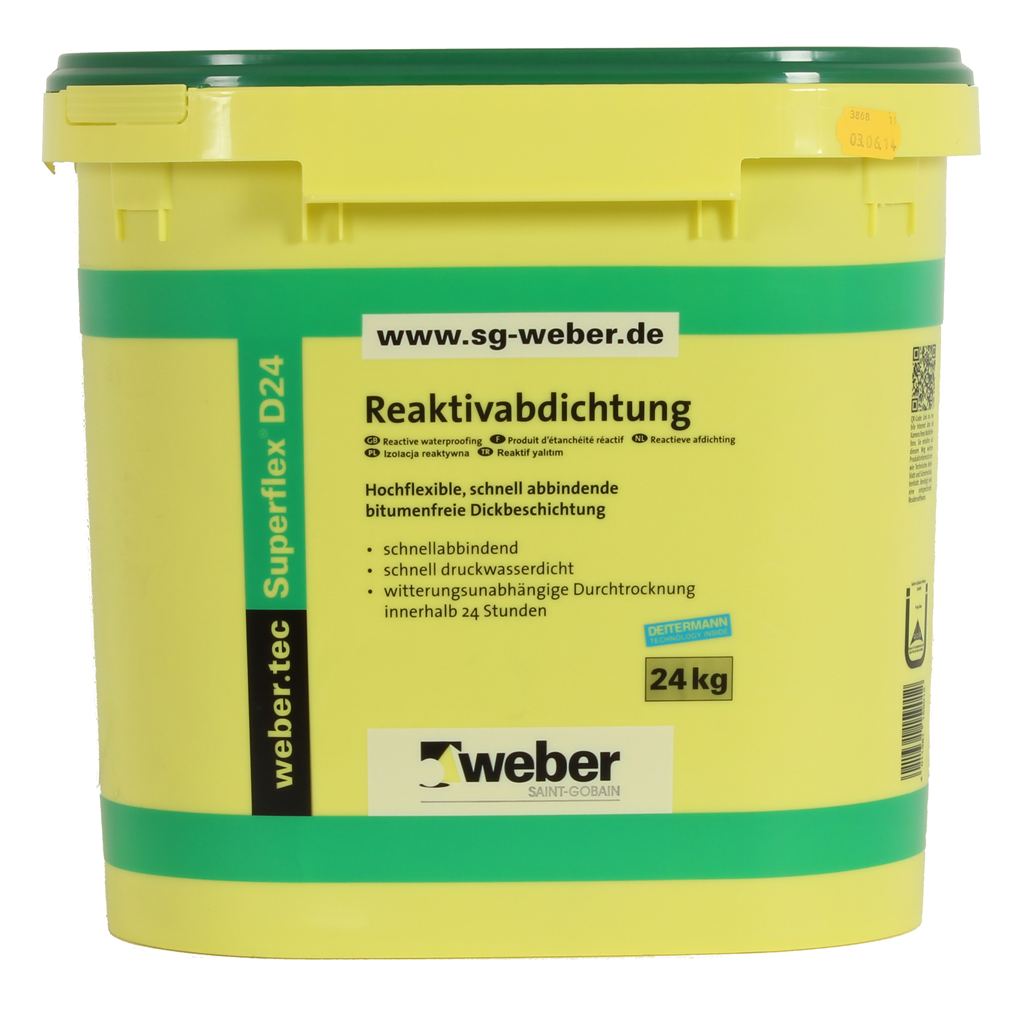

#Tec superflex full

weather-free time of full binding within 24 hours.based on cement, selected aggregate, special polymer in.2 mm per layer), in order to achieve surfaces with as few pores as Superflex D24 is a flexible, quick-setting, reactive, micro-mortar. The spray application should be carried out in several layers (max.Remove any hardened material residues on the packaging edges before mixing.In addition, the figure for the scratch layer – 1.0-1.5 kg/m² depending on the substrate roughness – must be added on top. The consumption figures given in this document will increase if the applicator lacks experience.Refer to our comprehensive document “General Guidelines for Waterproofing Works with Bitumen Thick Coatings” for full information related to important issues like assessment of water load, thickness control, and all execution details.Do not add any foreign substances during mixing and application.In the case of waterproofing water-impermeable concrete structures in the areas of working joints and butt joints of pre-cast concrete elements, comply with the national guideline (if existing) relating to such concrete structures.2018, issued by the German Construction Chemicals Association) and the WTA leaflet “Retrospective Waterproofing of Ground-Contacting Structures”. Follow the national standards and/or guidelines if not issued, and if requested, refer to the norm DIN 18533 “Waterproofing of Ground-contacting Building Structures”, the “Guideline for Planning and Execution of Waterproofing Works with Polymer-Modified Bitumen Coatings (PMBC)” (4th edition, Dec.Prior to backfilling the excavation pit use the fleece-lined drainage and protection foil weber.sys 983 over the basement walls in order to protect the waterproofing system.Do not bond protective boards or insulation boards and do not fill the excavation pit until the material has completely dried.In case of sunshine, carry out waterproofing works in shadow or in the morning or evening hours.In the case of pressure water steel-reinforced concrete must satisfy the national standards (EN 206) if not issued and if necessary, refer to DIN 1045.All characteristics mentioned in this data sheet are given for a temperature of +20 ☌, without draft and a relative rate of humidity of 50%.Limits of use: do not use for bonding foam glass insulation boards.sprayable with peristaltic pump and screw pump technology, e.g.resistant to thawing salts and freeze after full drying.resistant to ageing, to water attacking concrete up to the level "highly corrosive" in accordance with DIN 4030 (up to 3.000 mg sulphate per liter of water) and also to seawater.suitable for any mineral substrates no cement render is necessary on masonry.

In addition, for spot-bonding or full-surface bonding of extruded polystyrene rigid-foam boards used as protective, drainage or perimeter insulation boards (depending on the specific use) on the pre-said building parts. beneath floor concrete slab), foundations, ceiling slabs of car parking decks in cases of ground damp, non-pressure and pressure water.Īlso, convenient for the intermediate waterproofing of wet-duty rooms, not-inhabited balconies and terraces under floor screed. Weber.tec Superflex 100 S is used for the external waterproofing of masonry and concrete below ground level for earth-contacting basement walls, concrete floor slabs, lean concrete (i.e.

0 kommentar(er)

0 kommentar(er)